WHY MICHELIN REGROOVING?

Benefits Of Regrooving

Michelin truck and bus tyres are engineered for multi-life, and are therefore regroovable and retreadable!

Regrooving Q&A

Regrooving Indicators

Many Michelin tyres have a regrooving well in the centre of the tread wear indicators as a guide for high-quality regrooving. Some tyres do not have these indicators but are still fully designed for and ready to be regrooved. Just follow the steps detailed below to ensure the proper depth is obtained.

Michelin new tyre design regroove capability to extend life beyond the original tread depth.

Regrooving Steps

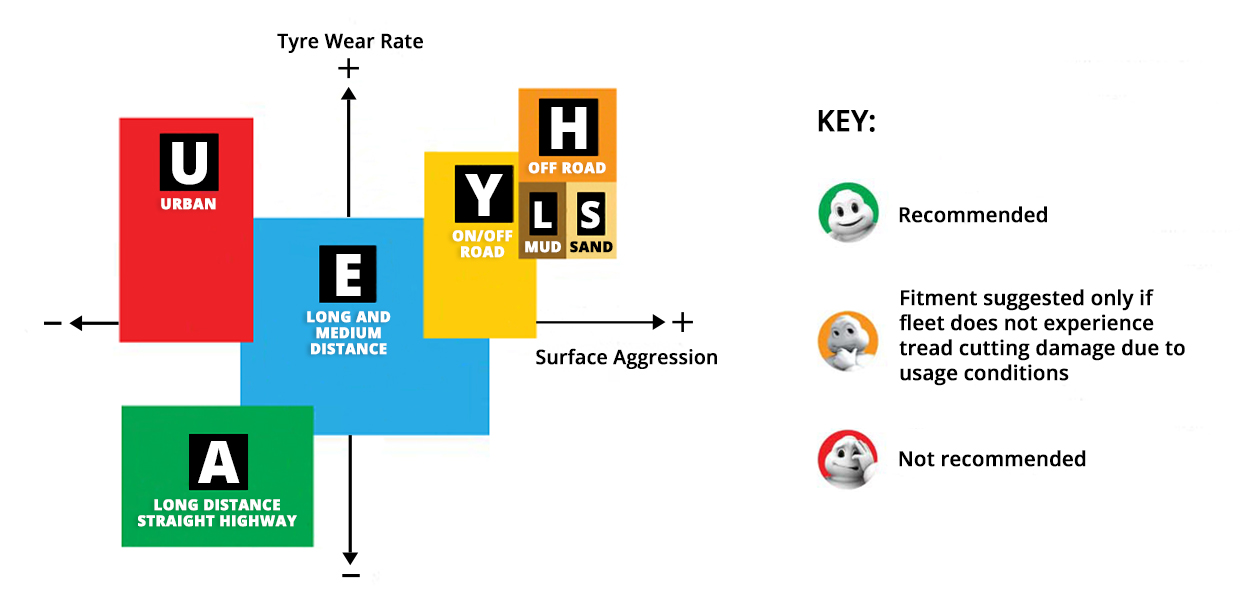

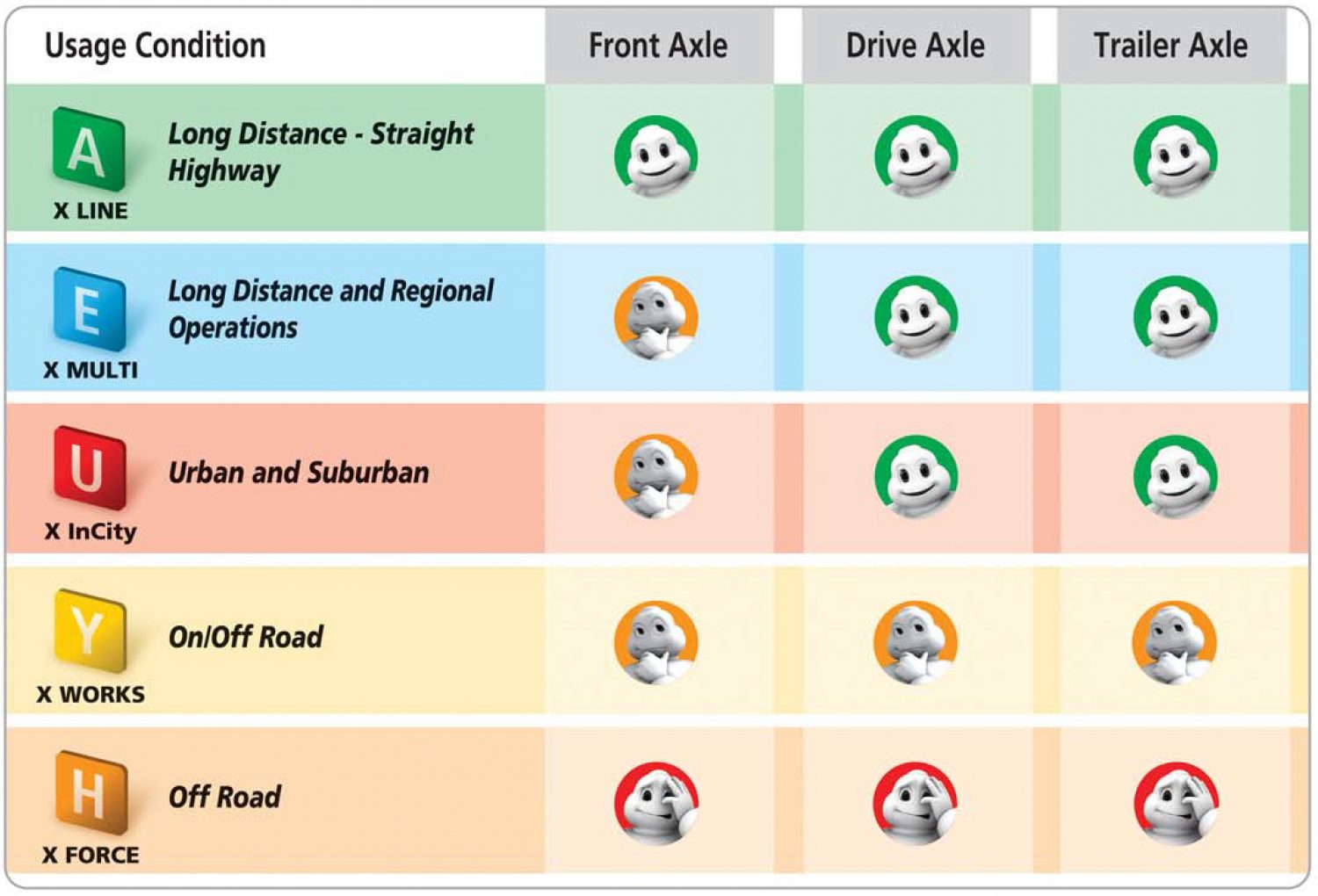

Regrooving For Different Usage Conditions

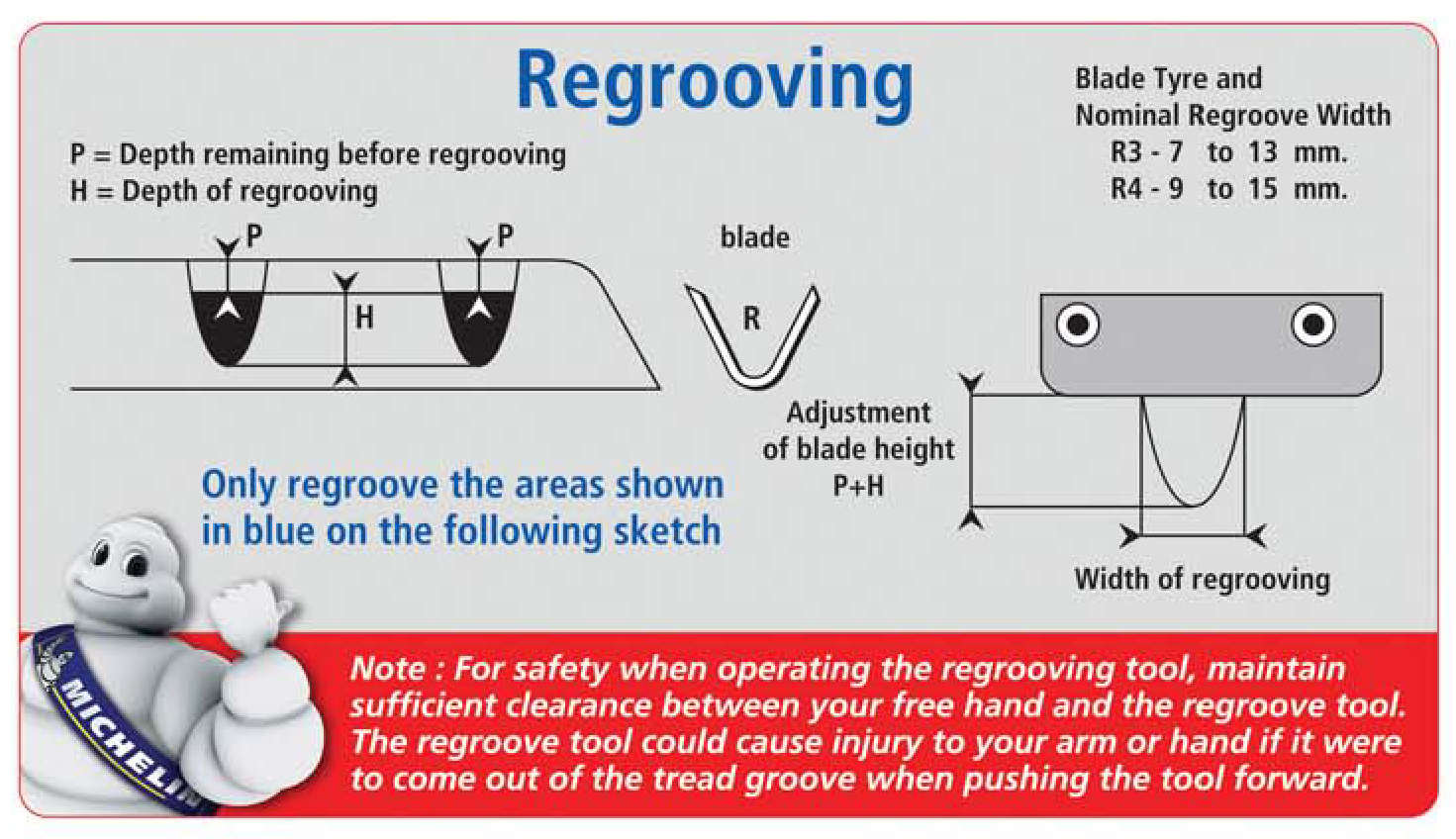

Regrooving Guidelines

Carry out the regrooving when there is still 2 to 4mm of tread.

This precaution makes it possible to:

- Reproduce the tread pattern easily.

- Adjust the regrooving depth so as to always keep at least 2 millimeters of compound between the bottom of the tread pattern and the crown layers.

If Regrooving is too deep it may:

-

Result in damage that could cause the premature destruction of the casing.

- Compromise the possibility of retreading.

- Allow metal layers of the crown to appear, which may reduce the life of the casing.

Regrooving is not recommended if the tread shows major damage. Damage may include:

- Multiple holes and cuts or areas where the tread has been torn off.

- Exposed metal layers of the crown that can be seen through damage or cuts

It is essential that the regrooving be carried out by professionals in accordance with the above guidelines.