MICHELIN’S TECHNICAL ADVICE & TRUCK MAINTENANCE TIPS

Learn the Basics to Master the Road

Welcome to everything you’ve ever wanted to know about truck tyres. The basics. How to select a tyre. What to look for in a tyre. How a tyre is built. How to inspect a tyre. And much more. The more you learn, the more you can improve your tyres’ tread life and your uptime.

How a Tyre is Built

More than 200 different materials are used to build a tyre. However, the main components of a tyre are natural rubber, synthetic rubber, steel, fabric materials and carbon black. Many different compounds can be present in one tyre, because different parts of the tyre perform different tasks.

3 Steps to Choose Your Tyre

- Decide on the correct use for your tyre Make your selection from among the ranges of MICHELIN tyres. Each range corresponds to different requirements and conditions of use for hauliers (long haul, urban, off-road…).

- Decide on the right size of tyre The maximum load for an axle is given by the vehicle manufacturer depending on current regulations. Simply fitting tyres that can bear a greater load to an axle does not mean it is possible to take on loads greater than those approved by the manufacturer. There are wheels that correspond to each size of truck tyre or tyres (width of rim): consult the ETRTO Standards Manual and/or the manufacturer’s recommendations. Never fit a tyre to an unapproved rim: there is a risk of damage to the wheel and/or tyre, insufficient contact patch, over working of the tyre casing, grip and longevity can also be affected.

- Choosing the right tread pattern Follow the criteria for choosing the tread pattern of truck tyres according to the position of the axle on the vehicle: F for Front Axle, D for Drive Axle, T for Trailer Axle, Z for all positions.

For more information, head over to Michelin’s Full Technical Databook.

Sizing and Identification

There is much more to a tyre’s sidewall than the tyre size. In fact, there can be as much as 25 different icons and descriptions. Learn how to read them, what they mean, and how you can choose the perfect tyre for you.

How to Read DOT Identification

The Department of Transportation (DOT) insignia is your tyre’s identification number. Think of it as a birth certificate for your tyre. It shows the plant where your tyre was manufactured, the week and year it was produced and more.

Michelin Tread Designations: An Identity for Every Tyre

Michelin uses specific names, numbers or letters to identify applications, tread patterns, casing construction or benefits. And beginning in 2012, Michelin started updating its commercial truck tyre names and sidewall markings to make their usage better understood by our customers. The new names such as MICHELIN® X® MULTI™, X® LINE™ and X® WORKS™ are easily visible on the sidewall.

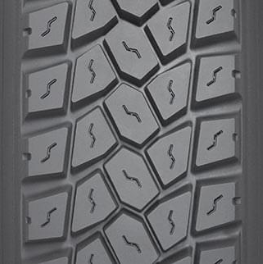

Rib Tread Design

Characterization: Grooves placed parallel to the bead, thus forming ribs, ranging in tread depths from 8.7mm to 18.2mm.

Benefits: Usually significantly better for fuel economy, although does not provide enhanced wet or snow traction.

Position: Usually found on the steering axle of a truck/tractor and on other free rolling axles such as trailers, dollies, tag and pusher axles. Also found on torque axles when traction is not a high priority.

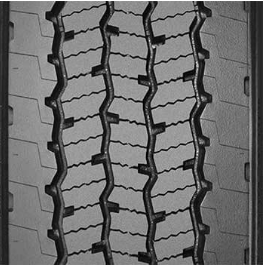

Block or Lug Tread Design

Characterization: Grooves placed laterally and perpendicular to the bead, ranging from 11.1mm to 25.4mm.

Benefits: Selected primarily for traction and improved mileage.

Position: Usually found on the drive or torque axle. The increased tread depth is needed to offset the scrubbing and/or spinning that can occur when power is transmitted to the drive axle.

How to Improve Mileage, Wear and Safety

The key to getting the most out of your tyre assets is proper maintenance. Constant care will keep your tyres rolling longer. If you follow our basic steps to tyre maintenance, your tyres can deliver maximum mileage, wear and safety for your trucks.

Proper Inflation: The Most Important Step of Tyre Maintenance

Many of today’s tyre problems are caused by insufficient or careless attention to tyre pressures. No tyre or tube is completely impervious to loss of air pressure. To determine the proper inflation pressure, all trucks should be weighed.

How to Weigh Your Truck

Be sure to weigh your vehicles, fully loaded, on a scale. Each axle, front and rear, and trailer must be weighed separately. Actual gross axle weights should be compared with the manufacturer’s tyre data book to determine the inflation pressure required. The load carried by each individual front axle tyre should be noted. If the maximum load-carrying capacity of the tyre is below the actual scale weight, greater carrying capacity tyres must be used, either a higher load index (load range or ply rating) or a larger tyre size.

The Effects of Under-Inflation

Under-inflation will increase the deflection of the sidewalls. The effect of over-flexing and the generation of too much heat will cause carcass fatigue and deterioration.

The Effects of Over-Inflation

The tyre carcass becomes more susceptible to damage in the form of shocks and rapid tread wear.

Tyre Wear

Tyre wear is the result of friction between the road and your tyre as it rolls. And friction is based upon many different properties, including the tyre’s rubber, the tyre’s load and inflation and the influence of the mechanical system (such as alignment and road surface).To achieve optimized tyre wear, the tyre should be properly aligned, properly inflated and carry the proper load weight. It would create a well-worn footprint and its weight would be evenly distributed over the footprint to maximize the tyre’s tread life. But this is the real world. Watch the video below to learn the fundamentals of tyre wear, and discover how tyre alignment affects your tyre’s wear.

The Importance of Tyre and Wheel Inspection

Pre-trip inspections increase safety and maximize uptime. Not to mention they are a regulatory requirement. Make sure you own a calibrated air gauge, and then follow the steps below. We’ve also created two videos to help get you started.

The Six Steps of Pre-Trip Inspection:

- Check your tyres for proper inflation. If a tyre is 20% below its targeted PSI, it is considered flat and should be inflated if not damaged. Also, dual tyres should be within 10 PSIs of each other.

- Check your valve caps to make sure they are properly secured.

- Look for tread wear and check proper tread depth. To learn the fundamentals of tyre wear.

- Check for tyre cuts or bulges in the sidewall.

- Check wheel and lug nut conditions. Make sure there is no rust or bends.

- Inspect suspension components.

Source: https://trucks.michelin.co.nz/technical-advice