MICHELIN’S 2048 AMBITION

Tyres will be made using 80 percent sustainable materials and 100 percent of tyres will be recycled.

Michelin took advantage of the 2018 edition of Movin’On, the world summit on sustainable mobility, held in Montreal, to announce its new strategy for the use of sustainable materials in tire manufacturing and the issue of their recycling. This commitment is perfectly in line with the Group’s 4R approach (Reduce, Reuse, Recycle and Renew), for a circular economy. Explanations.

MANUFACTURING TIRES WITH 80% SUSTAINABLE MATERIALS…

Today the worldwide recovery rate for tyres is 70% and the recycling rate is 50%. For a sustainable future, Michelin is investing in high technology recycling technologies to be able to increase this content to 80% sustainable material.

Using recycled and renewable materials

This ambitious sustainable development objective involves a commitment to research programs into bio-sourced materials, such as Biobutterfly, a program launched in 2012 with Axens and IFP Energies Nouvelles.

The Biobutterfly project involves the creation of synthetic elastomers from biomass such as wood, straw or beet.

Michelin acquires Lehigh Technologies

“This acquisition demonstrates Michelin’s strategic determination to capitalize on its expertise in high-tech materials, in areas that extend beyond the field of tyres. In particular, by promoting the use of innovative recycled materials from tires in a variety of non-pneumatic industrial sectors.”

Christophe Rahier, Director of the High Technology Materials Business Line at Michelin

Michelin is developing innovative solutions today in order to integrate more and more recycled and renewable materials in its tyres, while continuing to improve performance. This is demonstrated by the recent acquisition of the American company Lehigh Technologies, a specialist in high technology micro powders that are derived from recycled tyres.

Micronized Rubber Powders made from recycled tyres

Lehigh Technologies is based in Tucker near Atlanta (United States) and employs over 100 people. Lehigh Technologies designs and produces raw materials with high technological content, called Micronized Rubber Powders (or MRP). These are innovative materials that reduce the amount of non-renewable raw materials needed for tire production, such as elastomers or carbon black.

MRP is a low cost, efficient and sustainable material that can therefore be used as a substitute for other components used in the manufacture of tyres, as well as plastics, asphalt and construction materials.

Major world tire manufacturers, as well as companies specialized in asphalt and construction materials, among others, are already customers of Lehigh Technologies’.

100% of tyres recycled, worldwide

In 2018, according to the World Business Council for Sustainable Development (WBCSD), it is estimated that there will be 1 billion end-of-life tyres generated in the world, or around 25 million tons. 70% of these tyres are recovered, 50% of which are recycled, every year, and used in various forms, such as asphalt for example. The remaining 20% are transformed into energy. In comparison, 14% of plastic packaging or containers are recovered every year.

Investing in tyre recycling

Michelin is investing in high technology recycling so that by 2048 tyres are 100% recycled for the vehicles of the future. To achieve these ambitions, Michelin proposes to develop partnerships and identify new ways to recycle tyres, or new outlets for recycled tyres.

A Hackathon was held in 2017, in partnership with Alliapur, the organization that manages, in France, recycling on behalf of the main tire manufacturers, to brainstorm solutions in which tyre granulates could be used. The winner of this Hackathon was “Black Pillow”, which suggested creating safe urban furniture made of tyre granulates.

With huge potential gains

When all these ambitions are achieved, namely 80% of sustainable materials and 100% of recycled tires, the potential savings will be equivalent to:

- 33 million barrels of oil saved per year (16.5 supertankers), or 54,000 GWh

- One month’s total energy consumption of France

- 65 billion kilometers driven by an average sedan (8L / 100 km) per year

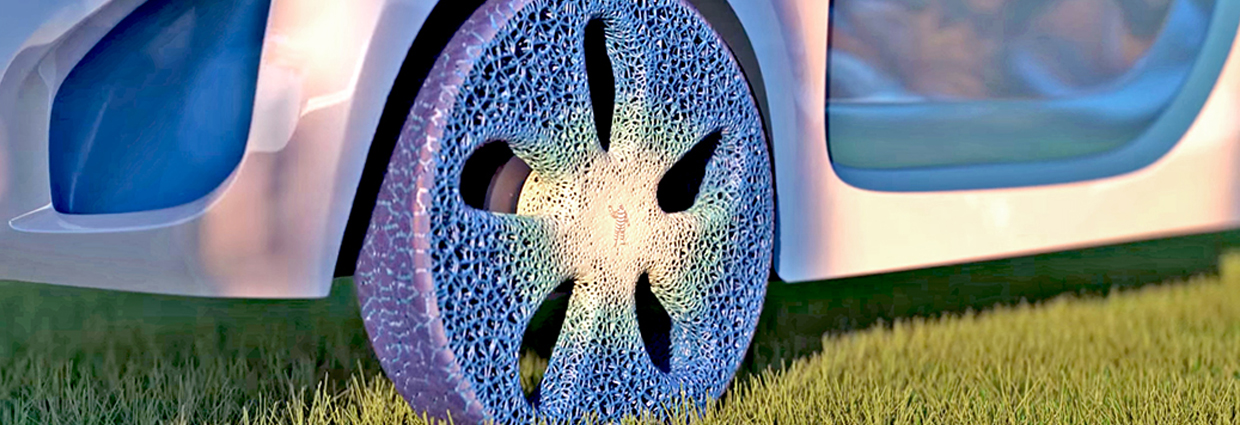

Michelin and the Vision Concept

Advanced materials and 3D printing technologies will be used to manufacture and renew the tread of this mobility solution and will mean that it is 100% recyclable.

The features of the VISION concept are:

- An airless tire made of bio-sourced and recycled products

- A connected eco-system within the tire, providing services and advice to the driver

- A bio-degradable tread that can be renewed with a 3D printer

Michelin and the “4R” Strategy